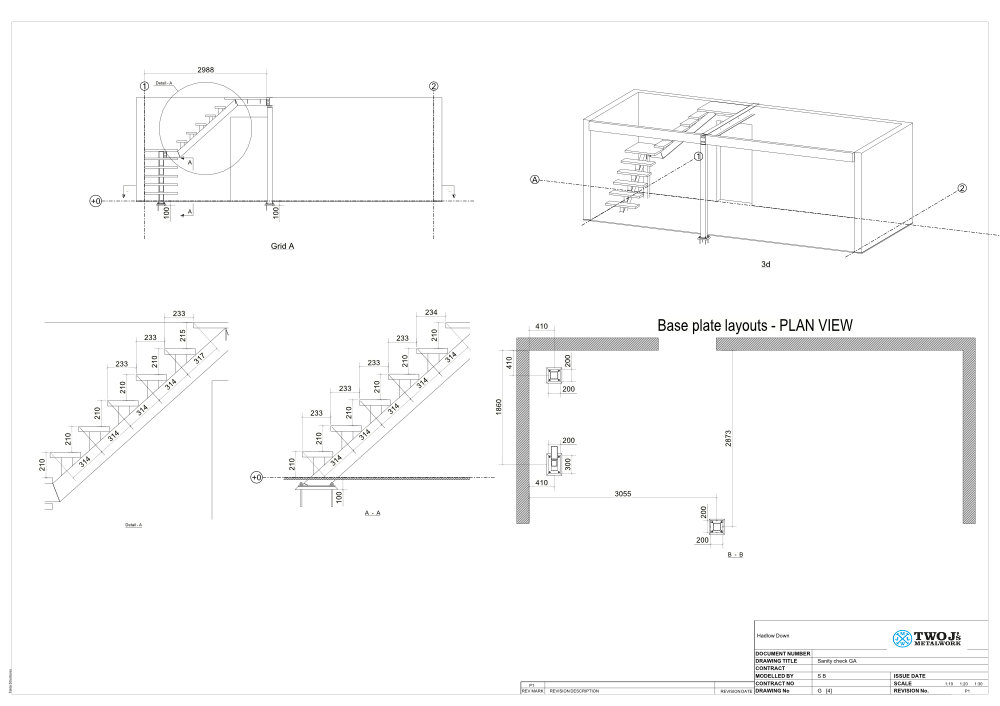

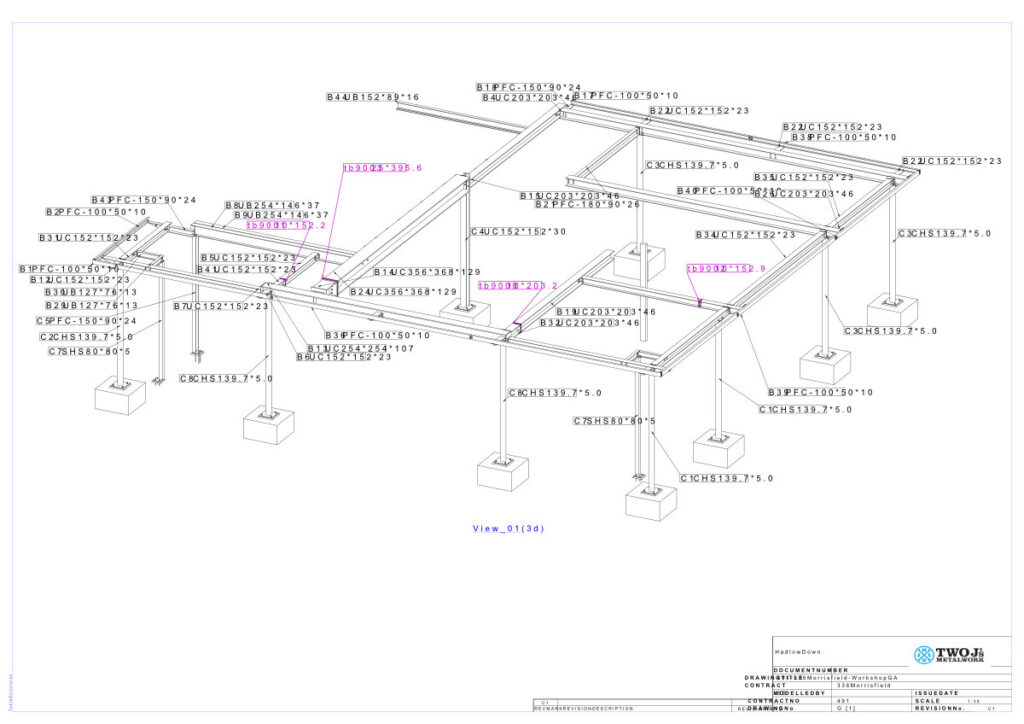

At Two J’s Metalwork, we create detailed 3D CAD drawings to ensure accuracy in every steelwork project. Our team produces precise 3D models, providing a clear, visual representation of each design. This method improves customer understanding and streamlines the fabrication process. Clients also receive 3D visualisations during the estimating phase, ensuring that the final product matches the original quote. With this approach, we eliminate guesswork and give clients complete confidence in their projects.

In-House Steel Detailing for Faster Turnarounds

Managing steel detailing in-house gives us full control over quality and efficiency. Our team quickly adjusts drawings based on customer feedback, keeping projects on track. By responding to changes immediately, we reduce delays and help clients stay on schedule.

Accurate Surveying for a Perfect Fit

Before drafting begins, our trained surveyors visit the site to take precise measurements. Collecting real-time data allows us to create steel components that fit seamlessly into the project. After finalising the drawings, our surveyors return to set out column bases with pinpoint accuracy, ensuring a smooth transition from design to fabrication.

Seamless Integration with TEKLA & CAD Technology

With TEKLA Structures detailing and cutting-edge CAD technology, we guarantee precision in every project. Whether fabricating a complex framework or a simple bracket, we deliver accurate designs that integrate flawlessly. Our 3D TEKLA models, combined with advanced project management software, allow real-time tracking from procurement to delivery.